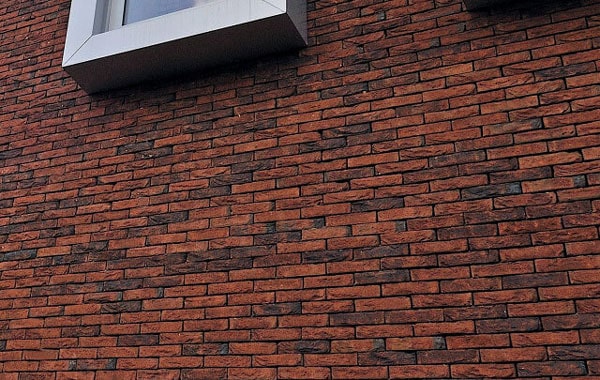

The types of fly ash brick in Lahore that are mostly used in Iran today for construction include machine-made bricks, solid-made bricks, perforated-made bricks, and hollow clay.

Bricks are different in terms of strength and appearance and are prepared with different dimensions depending on the use.

Bricks are divided into several categories based on the type of classification.

pressed brick: It is one of the oldest types of brick production.

The reason for the name of this type of brick is that in the beginning, its clay was pounded by hand and the corners of the mold were filled with special mud by manual pressure of clay workers.

This type of brick is usually used in building reinforcement and underlayment.

Types of pressed bricks: A)Green: They are heated more in the furnace and are very strong and durable and are categorized as high-quality bricks.

B)Boil: Boiled bricks are baked with soil that does not become pasty at a heat of more than a thousand degrees, and they keep it in the furnace until the grains of soil sweat a little and stick together and the brick becomes one piece.

In order for the brick to sweat less, it is treated with flux, which is usually iron oxide. Iron oxide, apart from being fusible, turns the color of the welded brick from red to black.

c)Raw: As its name suggests, the baking process of these bricks is not completed during the baking process.

For this reason, the color of these bricks is between the color of raw clay and the final brick.

However, this brick is completely inferior and should not be used in the bricklaying process.

These bricks must be re-baked and are usually placed in the same place as before in the brick kilns.

Your comment submitted.